ABE Timeline

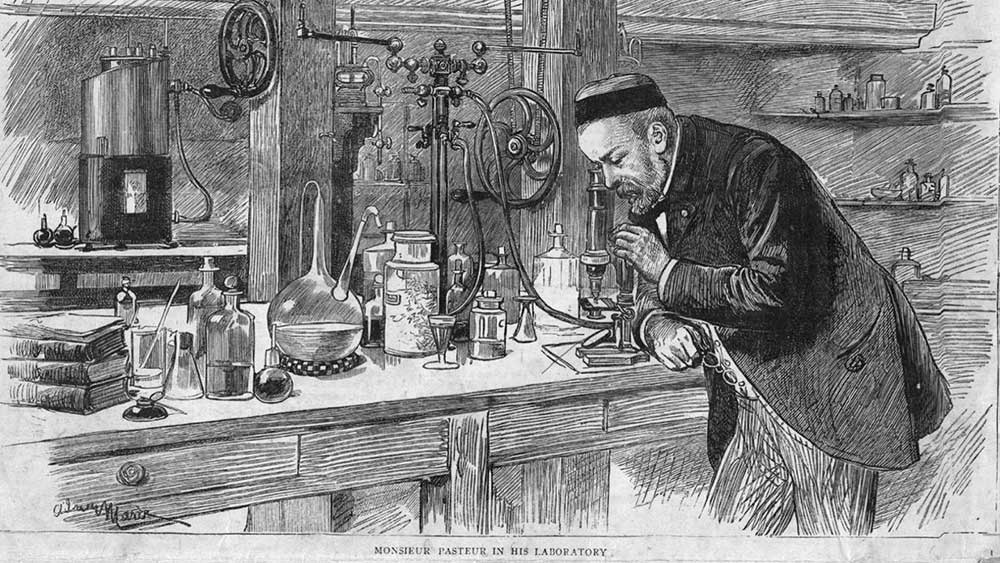

1861

Butanol production through microbial fermentation was reported for the first time by Louis Pasteur

1861

1905

microbial production of acetone observed by Franz Schardinger

1905

1912

Chaim Weizmann isolates the ABE bacterium Clostridium acetobutylicum

1912

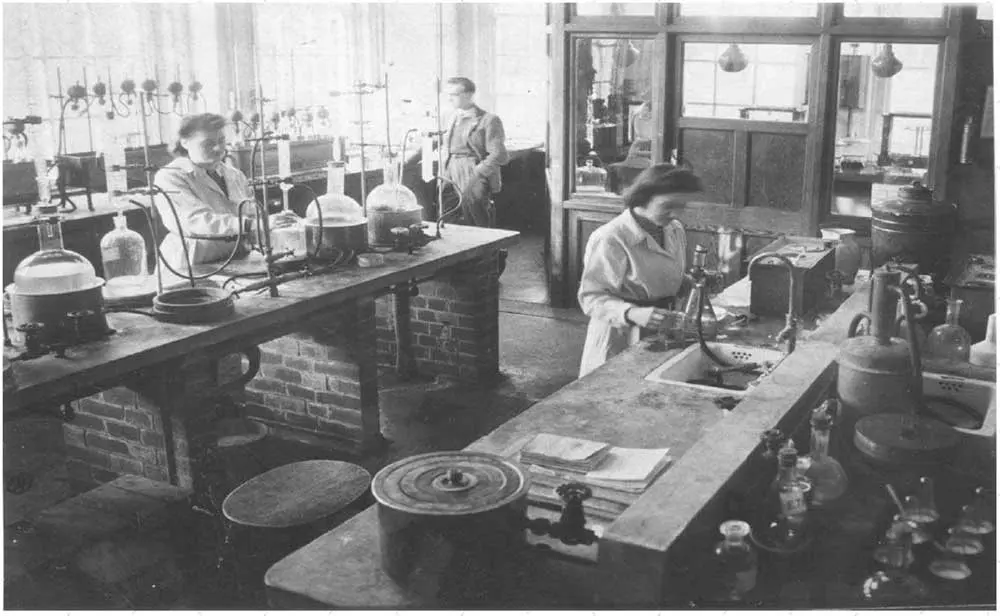

1916

commercial ABE production to make acetone for explosives in WW1

1916

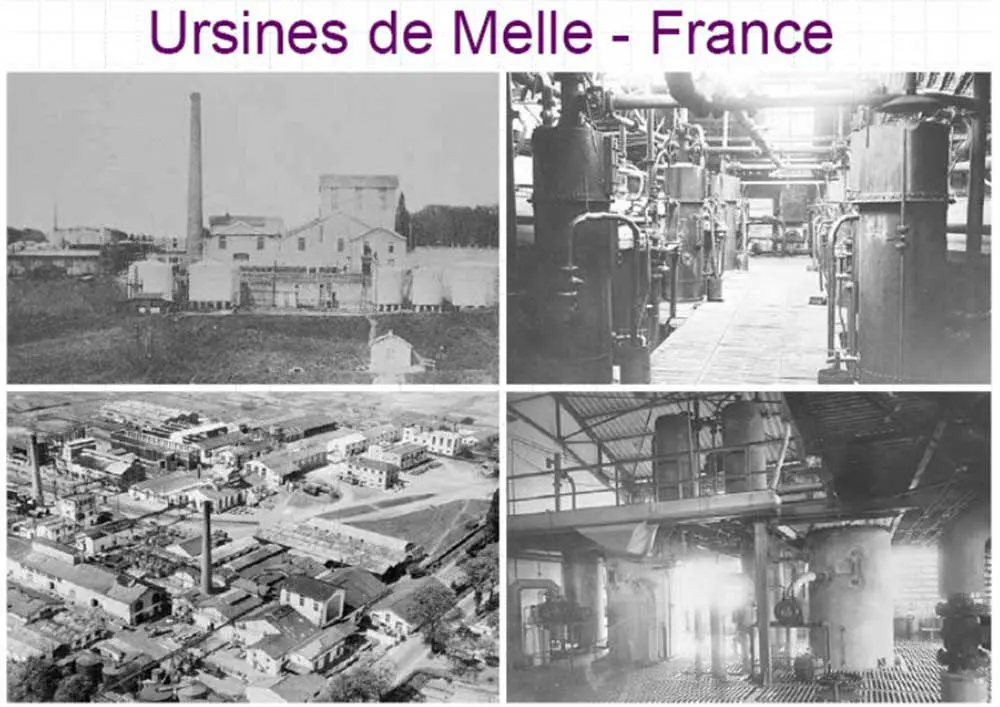

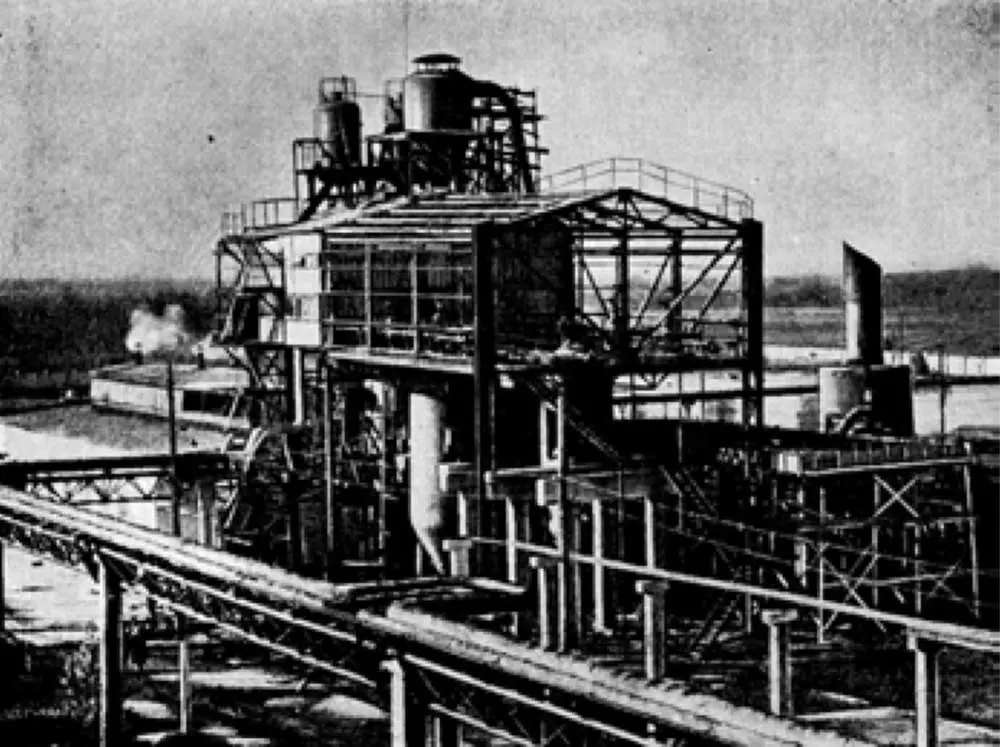

1920 - 1960

ABE process spreads all over the world – at its peak it was second only to ethanol production as a fermentation industry

1920 - 1960

1960

rise of the petrochemical industry provides a new source of chemicals and sees ABE plants closing down in the west, as the high cost of substrates undermines the ABE industry

1960

1980s

ABE facilities in South Africa and Russia close

1980s

2000s

ABE plants in China close down

2000s

2005

David Ramey drives an unmodified car 10,000 miles across the USA powered entirely on butanol

2005

2005

Interest in ABE is rekindled – plants start to re-open in China and new ABE companies begin to emerge

2005

2012

Celtic Renewables is formally launched

2012